Diamond Manufacturing

The manufacturing of diamonds is a meticulous process that transforms rough stones into brilliant, polished gems. This craft primarily takes place in key diamond hubs around the world, with India leading the industry—polishing 90% of all diamonds. Other notable hubs include Antwerp and China, where cutting-edge technology meets exceptional craftsmanship. Polishing rough diamonds involves precision cutting and shaping to maximize their brilliance and value.

In many diamond-producing countries, manufacturing also contributes to local economies through beneficiation programs, which aim to create jobs, enhance skills, and ensure that more of the diamond value chain benefits the local communities.

Different Stages of the Manufacturing Proces

- Planning

Planning is the foundation of diamond manufacturing, where every decision impacts the final product's value. Using advanced imaging tools like 3D modeling, experts map the rough diamond's internal structure. These technologies allow planners to identify inclusions, determine the most efficient cuts, and decide if the diamond will be divided into multiple stones. The goal is to maximize yield while preserving clarity and brilliance.

- Cleaving or Sawing

Once a plan is finalized, the diamond is divided into smaller sections. Cleaving splits the stone along natural grain lines, while sawing—using lasers or high-speed diamond saws—handles more complex cuts. This step prepares the diamond for further shaping.

- Bruting

Bruting shapes the diamond into a rough outline of its final form, focusing on symmetry. During this process, one diamond is used to grind another, forming a precise girdle (the outer edge). Symmetry and proportions established here are critical to the diamond’s brilliance.

- Faceting

Faceting is the most intricate stage, where skilled artisans cut and polish the individual facets of the diamond. Blocking creates the primary facets, such as the table (top facet) and pavilion (lower facets), while brillianteering refines additional facets for optimal sparkle. Even minor misalignments during this stage can significantly affect the diamond’s brilliance.

- Polishing

Polishing is the final step in the process, where a spinning scaife (a polishing wheel coated with diamond powder) is used to perfect each facet. A skilled polisher ensures that the stone’s symmetry, angles, and surfaces achieve maximum brilliance and fire.

Polishing of High-End Stones: only in Antwerp

Antwerp is globally recognized for its unparalleled expertise in polishing high-end diamonds, combining centuries of craftsmanship with cutting-edge technology. Although the number of polishers active in Antwerp has significantly declined in recent years (due to lower labor costs in countries such as India, for example), the polishers who remain today are the very best in the world.

The process begins with a scan of the rough diamond, using advanced scanning techniques to create algorithms that maximize the diamond's yield. This analysis considers both the external features and internal imperfections of the stone, ensuring a precise understanding of its potential.

Through these state-of-the-art algorithms, experts determine the optimal combination of polished diamonds that can be crafted from the rough stone, thus achieving the highest possible value. Modern laser techniques are then employed to cut the diamond into sections, allowing for the creation of intricate shapes with remarkable precision.

The final polishing stage is executed by Antwerp’s highly skilled professionals, whose mastery ensures every facet is polished to perfection. This blend of science and artistry defines Antwerp as the world’s premier hub for diamond excellence, delivering extraordinary results that continue to set the standard in the global diamond industry.

What is Beneficiation?

Diamond beneficiation is the process of adding value to rough diamonds by performing downstream activities such as cutting, polishing, and manufacturing within the countries where the diamonds are mined. This approach aims to maximize the economic benefits for resource-rich nations by ensuring that a larger portion of the diamond's value chain remains local.

The main objectives of beneficiation are to create jobs, develop a skilled workforce, and promote economic growth. By processing diamonds domestically, countries can reduce their reliance on exporting rough stones and capture more of the profits from their natural resources.

Several diamond-producing nations have adopted beneficiation policies, with Botswana being one of the most notable success stories. Through its partnership with De Beers, Botswana has established local cutting and polishing factories, creating thousands of jobs and transforming Gaborone into a global diamond trading hub. Similarly, Namibia and South Africa have implemented measures to ensure that a percentage of mined diamonds are processed locally.

However, beneficiation comes with challenges. Countries face stiff competition from established diamond polishing centers like Surat, India, where labor costs are low, and large-scale operations dominate. Additionally, developing the technical expertise and infrastructure required for high-quality diamond manufacturing can take years. These factors often make local processing more expensive and less competitive in global markets.

Despite these hurdles, diamond beneficiation is a powerful tool for economic development. It allows diamond-rich nations to foster sustainable industries, build expertise, and ensure that their natural resources contribute to long-term growth. As a result, beneficiation has become a key element in the diamond manufacturing process, bridging the gap between mining and the final polished product.

57 Facets: A brilliant (Antwerp) Story

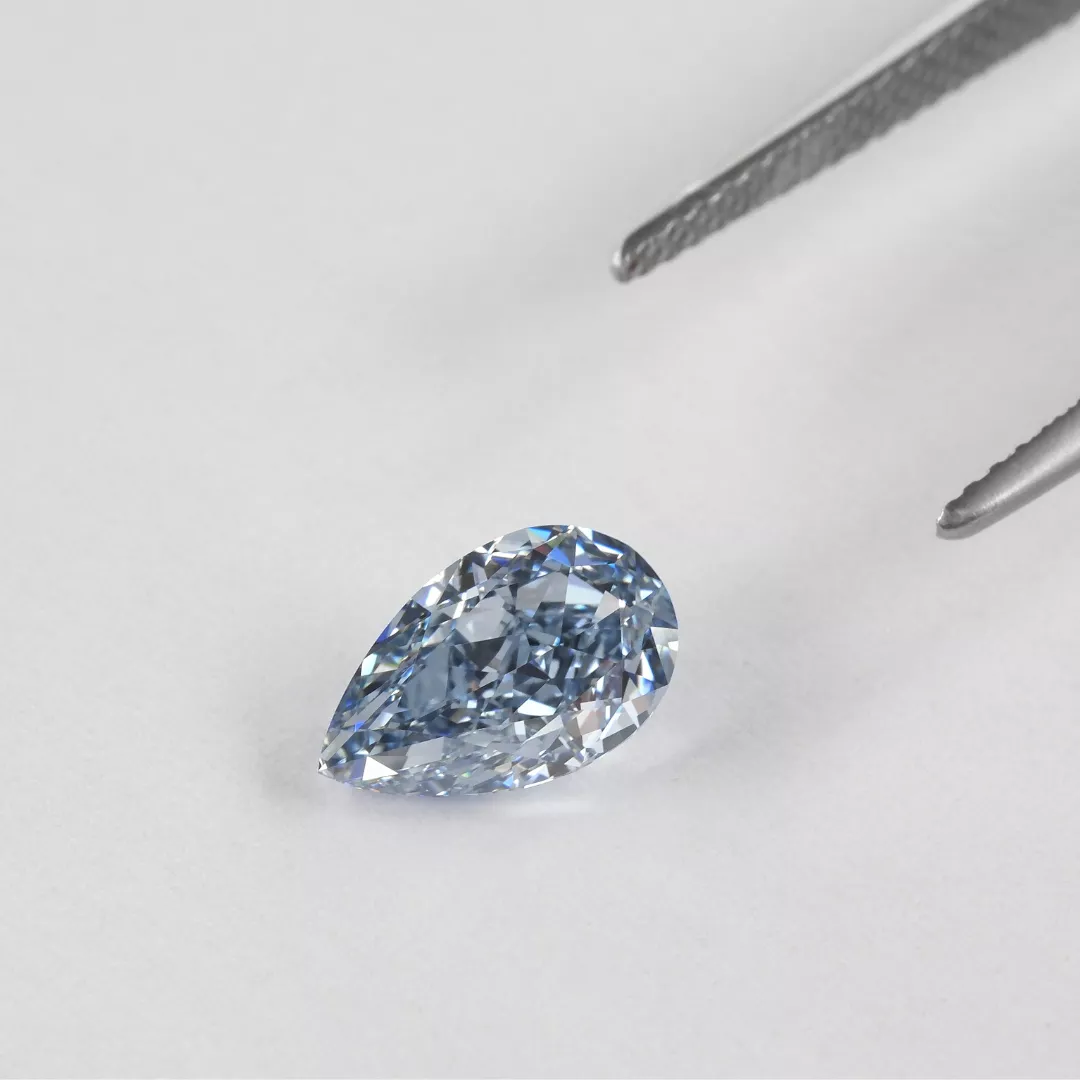

Diamonds are crafted in a variety of shapes—heart, pear, marquise, baguette, ...—but the most iconic and widely recognized is the round brilliant cut.

With 57 meticulously polished facets, this cut is designed to maximize the diamond's brilliance, sparkle, and light performance.

The round brilliant cut owes its precision and enduring appeal to Marcel Tolkowsky, a mathematician and gemologist from Antwerp, who in the 1920's was the first to mathematically analyze and define the proportions and angles required for optimal brilliance. His work established the "ideal cut," which remains the standard for diamond cutting to this day.

While Tolkowsky did not invent the brilliant cut, his mathematical approach solidified its status as the ideal form. The origins of the brilliant cut can be traced to the 17th century with the introduction of the “Mazarin” cut, which featured 16 facets on the crown. This was followed by the “Peruzzi cut,” developed by Venetian polisher Vincent Peruzzi, which increased the number of crown facets to 32.

Over time, gradual advancements in cutting techniques led to the Old European Cut, a predecessor to the modern brilliant cut. These earlier versions were typically square-shaped with rounded corners. The development of mechanical bruting in the 19th century enabled the production of perfectly circular stones, further refining the brilliant cut into the round brilliant we recognize today.